This study investigates the effect of the soil deflector’s opening angle on the quality of soil processing and uniform fertilizer distribution in agricultural activities, particularly in orchards and vineyards. The soil deflector temporarily blocks soil movement, facilitating the penetration of fertilizers into the soil, improving their integration with the soil environment. The dynamics of normal forces acting on soil particles are analyzed to understand their influence on the deflector's operational effectiveness. Results indicate that an opening angle between 54° and 66° significantly improves soil processing efficiency, achieving both uniform fertilizer application and optimal energy usage. The experiments explored variations in the soil deflector’s opening angle from 50° to 80° at speeds of 6 km/h and 8 km/h. Findings demonstrate that within the optimal angle range, the depth and width of fertilizer application improve markedly, ensuring better soil and nutrient management. The study further highlights that the resistance faced by the deflector decreases at smaller angles, whereas larger angles increase energy consumption and reduce fertilizer distribution efficiency. The research concludes that optimizing the soil deflector's opening angle is crucial for enhancing soil processing performance, improving fertilizer application uniformity, and minimizing energy expenditure. These results provide practical guidelines for the development of agricultural machinery that meets the needs of modern, resource-efficient farming practices, particularly in specialized environments like orchards and vineyards.

| Published in | Engineering and Applied Sciences (Volume 10, Issue 1) |

| DOI | 10.11648/j.eas.20251001.11 |

| Page(s) | 1-6 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2025. Published by Science Publishing Group |

Soil Screen, Normal Force, Traction Resistance, Fertilizer Distribution, Agricultural Activities, Soil Processing Efficiency

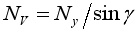

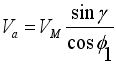

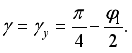

(1)

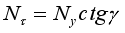

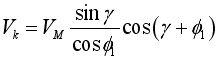

(1)  ,(2)

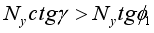

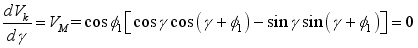

,(2)  (3)

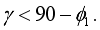

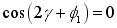

(3)  (4)

(4)  (5)

(5)  ,(6)

,(6)  (7)

(7)  (8)

(8)  (9)

(9)  (10)

(10) SS | Soil Screen |

OA | Opening Angle |

| [1] | Muxammadjonovich, K. N., Abduxalilovich, I. I. Substantiation of Deep Softener Parameters that Cut the Vine Roots and Apply Fertilizer in a Wide-Band Manner. Central Asian Journal of Theoretical and Applied Science, 2021. 2(12), pp. 56-59. |

| [2] | Temirov, S., Tukhtabayev, M., & Turgunov, Z. Studying the movement of fertilizers in the fertilizer spreader. In E3S Web of Conferences 2023. Vol. 386, p. 03007. |

| [3] | Vrignon-Brenas, S., Fontez, B., Caboulet, D., Ruetsch, G., Demarle, O., Metay, A., & Pellegrino, A. (2024). How to combine soil and plant indicators to manage nitrogen fertilisation in vineyards? Heliyon, 10(21). |

| [4] | Raximberdiyevich, A. N., Davlataliyevich, A. N., & Akhmadjanovich, M. T. (2023, November). Influence of machine-tractor units on soil compaction in Tillage. In AIP Conference Proceedings (Vol. 2821, No. 1). AIP Publishing. |

| [5] | Soliev, H. M., Akhmadjanovich, M. T., & Turgunov, Z. X. (2023, November). Energy performance of wide-width cotton seed sowing aggregate. In AIP Conference Proceedings (Vol. 2821, No. 1). AIP Publishing |

| [6] | Pádua, L., Chojka, A., Morais, R., Peres, E., & Sousa, J. J. (2024). Versatile method for grapevine row detection in challenging vineyard terrains using aerial imagery. Computers and Electronics in Agriculture, 226, 109372 |

| [7] | Misic V. Priemena automatsre bocne tanjirzau abrali plantazneh varnjakka / Zugosl Vorastvo, 1985, g. 9, br 33/34, – pp. 155-157. |

| [8] | Khudayarov B. M., Kuziev U. T., Sarimsakov B. R. The dependency of the distance of throwing soil to the size of the working body // International Journal of Research Culture Society. – India, 2019. –Volume-3, Issue-10, Pages: 45-49. |

| [9] | Temirov, S. U., Nuriddinov, A. D., & Tukhtabaev, M. (2021). The Results of Determining of Working Depth Stability of the Universal Working Body and Width of Lateral Spread of Soil. Int. J. Advanced Research in Science, Engineering and Technology (IJARSET), 8(5). |

| [10] | Kamilov, N., Yergas’ hev, M., & Abduvahobov, D. Determination of parameters and operating values of organic fertilizer. Journal of Critical Reviews, 2020. 7(13), pp. 1387-1395. |

| [11] | Muxammadjonovich, K. N. Abduxalilovich II Substantiation of Deep Softener Parameters that Cut the Vine Roots and Apply Fertilizer in a Wide-Band Manner. Central Asian journal of theoretical & applied sciences, 2021. 2(12), pp. 56-59. |

| [12] | Khojiyev, A., & Komilov, N. Choosing the type of earth bed forming operating element. In Independent training of competitive personnel: cooperation of world education system with higher education institutions” Materials collection of Republican scientific-practical conference, 2010. pp. 76-78. |

| [13] | Komilov, N. M. M. Research of motion of fertilizers particles on machine drum blades for fertilizers distribution. Europaische Fachhochschule, 2015. 6, pp. 70-72. |

| [14] | Muhammadjonovich, K. N. M. Theoretical bases of forming an earth bed by means of spherical disks. European science review, 2018. 3-4, pp. 251-252. |

| [15] | Nishonov, B., Normirzaev, A., & Tukhtabayev, M. Study on the development of a rotary soil softener. In E3S Web of Conferences, 2023. Vol. 434, p. 03013. |

APA Style

Shokhrukh, A. (2025). The Influence of the Soil Screen Opening Angle on the Quality of Tillage and Fertilizer Distribution. Engineering and Applied Sciences, 10(1), 1-6. https://doi.org/10.11648/j.eas.20251001.11

ACS Style

Shokhrukh, A. The Influence of the Soil Screen Opening Angle on the Quality of Tillage and Fertilizer Distribution. Eng. Appl. Sci. 2025, 10(1), 1-6. doi: 10.11648/j.eas.20251001.11

@article{10.11648/j.eas.20251001.11,

author = {Abduganiyev Shokhrukh},

title = {The Influence of the Soil Screen Opening Angle on the Quality of Tillage and Fertilizer Distribution},

journal = {Engineering and Applied Sciences},

volume = {10},

number = {1},

pages = {1-6},

doi = {10.11648/j.eas.20251001.11},

url = {https://doi.org/10.11648/j.eas.20251001.11},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.eas.20251001.11},

abstract = {This study investigates the effect of the soil deflector’s opening angle on the quality of soil processing and uniform fertilizer distribution in agricultural activities, particularly in orchards and vineyards. The soil deflector temporarily blocks soil movement, facilitating the penetration of fertilizers into the soil, improving their integration with the soil environment. The dynamics of normal forces acting on soil particles are analyzed to understand their influence on the deflector's operational effectiveness. Results indicate that an opening angle between 54° and 66° significantly improves soil processing efficiency, achieving both uniform fertilizer application and optimal energy usage. The experiments explored variations in the soil deflector’s opening angle from 50° to 80° at speeds of 6 km/h and 8 km/h. Findings demonstrate that within the optimal angle range, the depth and width of fertilizer application improve markedly, ensuring better soil and nutrient management. The study further highlights that the resistance faced by the deflector decreases at smaller angles, whereas larger angles increase energy consumption and reduce fertilizer distribution efficiency. The research concludes that optimizing the soil deflector's opening angle is crucial for enhancing soil processing performance, improving fertilizer application uniformity, and minimizing energy expenditure. These results provide practical guidelines for the development of agricultural machinery that meets the needs of modern, resource-efficient farming practices, particularly in specialized environments like orchards and vineyards.},

year = {2025}

}

TY - JOUR T1 - The Influence of the Soil Screen Opening Angle on the Quality of Tillage and Fertilizer Distribution AU - Abduganiyev Shokhrukh Y1 - 2025/01/07 PY - 2025 N1 - https://doi.org/10.11648/j.eas.20251001.11 DO - 10.11648/j.eas.20251001.11 T2 - Engineering and Applied Sciences JF - Engineering and Applied Sciences JO - Engineering and Applied Sciences SP - 1 EP - 6 PB - Science Publishing Group SN - 2575-1468 UR - https://doi.org/10.11648/j.eas.20251001.11 AB - This study investigates the effect of the soil deflector’s opening angle on the quality of soil processing and uniform fertilizer distribution in agricultural activities, particularly in orchards and vineyards. The soil deflector temporarily blocks soil movement, facilitating the penetration of fertilizers into the soil, improving their integration with the soil environment. The dynamics of normal forces acting on soil particles are analyzed to understand their influence on the deflector's operational effectiveness. Results indicate that an opening angle between 54° and 66° significantly improves soil processing efficiency, achieving both uniform fertilizer application and optimal energy usage. The experiments explored variations in the soil deflector’s opening angle from 50° to 80° at speeds of 6 km/h and 8 km/h. Findings demonstrate that within the optimal angle range, the depth and width of fertilizer application improve markedly, ensuring better soil and nutrient management. The study further highlights that the resistance faced by the deflector decreases at smaller angles, whereas larger angles increase energy consumption and reduce fertilizer distribution efficiency. The research concludes that optimizing the soil deflector's opening angle is crucial for enhancing soil processing performance, improving fertilizer application uniformity, and minimizing energy expenditure. These results provide practical guidelines for the development of agricultural machinery that meets the needs of modern, resource-efficient farming practices, particularly in specialized environments like orchards and vineyards. VL - 10 IS - 1 ER -